Heat Transfer Losses in Oil & Gas: Why Insulation is Your First Line of Defense

- Omar Obaid

- Jul 20, 2025

- 14 min read

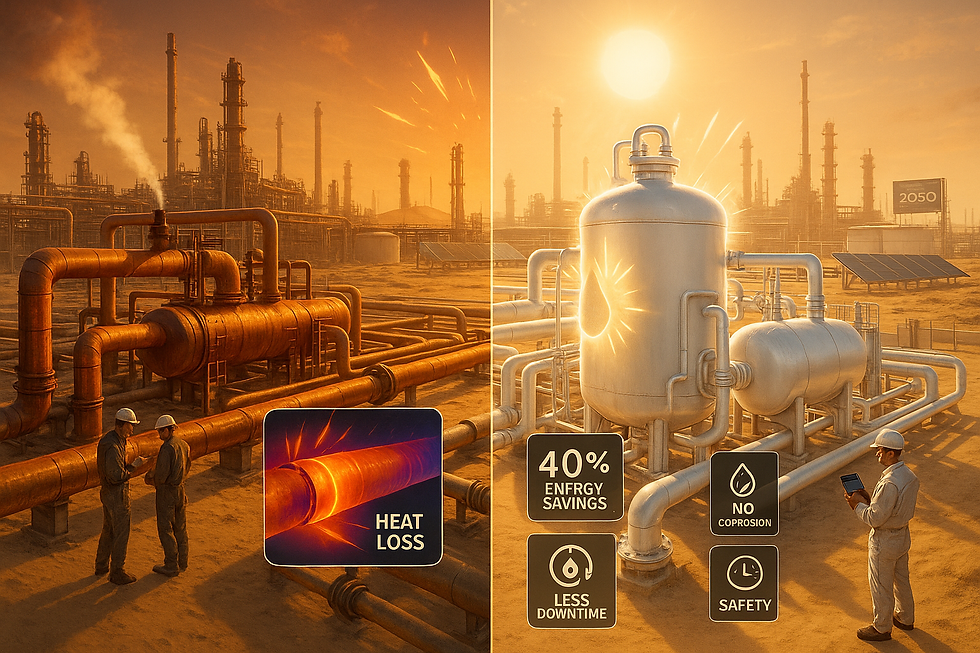

A technician inspects insulated pipelines at an oil and gas facility. Quality thermal insulation is vital to maintain process temperatures, reduce energy waste, and protect personnel from hot surfaces

Understanding Heat Transfer Losses in Oil & Gas

In the oil and gas industry, countless processes involve high temperatures – from steam pipelines and reactors to boilers and heat exchangers. Heat transfer losses refer to the thermal energy that escapes from these hot systems into the surrounding environment. When uninsulated or under-insulated equipment loses heat, it directly equates to wasted fuel and inefficiency. For example, research shows that reducing heat loss by 50% can be as simple as doubling the insulation thickness or halving the insulation material’s thermal conductivity . In other words, adequate insulation is crucial to control heat loss and maintain energy inside the process.

Heat losses are more than just a theoretical concern – they have real economic and safety impacts. An uninsulated pipeline or vessel will continuously dissipate heat, forcing boilers or heaters to work harder to maintain process temperatures. This wasted energy means higher operating costs and often higher fuel consumption (and thus more emissions). Moreover, surfaces that are not insulated can become dangerously hot to the touch , posing burn risks to workers and increasing the chance of heat-related equipment damage. In summary, heat loss in oil & gas operations leads to lower energy efficiency, higher costs, and potential safety hazards if left unmitigated.

Heat losses can occur through all modes of heat transfer: conduction, convection, and radiation. For instance, a steel pipe carrying hot oil will conduct heat to its outer surface, convect heat to ambient air, and radiate heat as infrared energy. If that pipe runs long distances (common in refineries or petrochemical plants), the cumulative heat loss can be substantial. Studies on pipelines have found that heat loss tends to increase nearly linearly with pipeline length, and without proper insulation, a long hot pipeline might lose 10–30% of its heat along the way . Clearly, identifying and minimizing heat transfer losses is essential for operational efficiency in oil and gas facilities.

Insulation: The First Line of Defense Against Heat Loss

To combat heat losses, thermal insulation is the first and best line of defense. Insulation works by introducing a barrier material with low thermal conductivity between the hot equipment and the cooler environment . In doing so, it slows down the flow of heat, keeping the energy where it’s needed inside pipes, tanks, and process equipment – rather than letting it escape. Proper insulation helps maintain the desired temperature of fluids and gases throughout the process, delivering them at the required temperature with minimal losses . In a process plant, for example, an insulated pipe can prevent the 5 1 5 f luid flowing inside from losing heat to the surroundings, ensuring it reaches its destination at the desired outlet temperature

Why is insulation considered the “first line of defense”? The reason is that it directly addresses the problem at its source: by reducing the rate of heat transfer, insulation immediately cuts down energy waste. This translates to several key benefits

• Energy Efficiency and Cost Savings: By preventing heat loss, insulation reduces the amount of fuel needed to keep processes at temperature. This improved efficiency can yield significant cost savings over time. In fact, insulating pipelines and equipment helps maintain product temperature and directly reduces energy costs. Less heat lost means less energy burned – saving money on fuel bills while also lowering carbon emissions.

Operational Stability: Good insulation ensures more stable temperatures for process fluids. Equipment can operate closer to design conditions without as much compensation for heat losses. This stability can improve product quality and throughput because heaters and boilers aren’t constantly cycling to make up for lost heat.

Safety and Workplace Comfort: Thermal insulation also doubles as a safety measure. It keeps external surface temperatures lower, which protects workers from burns and reduces ambient heat in facilities. Many industrial accidents are avoided by simply insulating hot pipes that run alongside platforms or work areas. As one industry source notes, effective insulation plays a significant role in ensuring efficient and safe operations across oil & gas facilities

Equipment Longevity: When equipment isn’t exposed to extreme temperature swings (thanks to insulation retaining heat), there is less thermal stress on metals and welds. Furthermore, certain insulation materials can protect against corrosion by keeping moisture off of pipes. All of this means a longer lifespan for expensive equipment. Insulation really becomes a form of asset protection in the oil and gas sector

Environmental Compliance: By saving energy, insulation helps cut emissions indirectly (since burning less fuel means emitting less CO₂). For companies aiming to meet sustainability targets or comply with emissions regulations, insulation is a low-hanging fruit solution to improve their environmental footprint. It’s no surprise that adding or upgrading insulation is often one of the first recommendations in energy audits for industrial plants.

It’s worth emphasizing just how effective insulation can be in reducing heat loss. Even a few inches of a good insulator can drastically drop the heat flow. In technical terms, insulation materials are rated by their R value (thermal resistance); higher R-value means better insulation performance. Multiple layers of insulation simply add up their R-values – so doubling the thickness roughly doubles the thermal resistance. This is why an investment in insulation often pays for itself: one study found that simply doubling insulation thickness can cut heat loss in half , a clear demonstration of insulation’s powerful impact

Challenges with Traditional Insulation Materials

Conventional insulation materials used in the oil and gas industry include mineral wool (rockwool), f iberglass batts or blankets, calcium silicate, and various foam wraps. These materials have been industry staples for years and do provide decent thermal resistance under ideal conditions. For example, dry rockwool can offer an R-value of around 3 per inch, and fiberglass around 2.5 per inch . They are used to 9 2 insulate pipelines, vessels, and equipment by wrapping the equipment in thick layers and then usually adding an outer cladding (jacketing) to protect the insulation.

However, traditional insulations have several limitations, especially in harsh industrial and Middle Eastern climate conditions:

Moisture and Corrosion Issues: Perhaps the biggest issue is that materials like fiberglass and rockwool are highly absorbent and prone to soaking up water if the protective cladding is damaged or if condensation forms . Wet insulation not only loses its insulating ability (water is a good conductor of heat), but it also becomes a conduit for corrosion under insulation (CUI). When insulation gets wet, it holds water against the steel pipes or tanks, promoting rust and corrosion out of sight. Over time, CUI can cause severe wall thinning or equipment failure. As industry experts warn, once moisture intrudes, traditional insulations “lose their protective benefits and become a facilitator of corrosion under insulation” . This is a major maintenance headache in oil & gas facilities – companies must frequently inspect and replace soaked insulation and repair any corroded sections of pipe.

Degradation in Harsh Conditions: In the Middle East’s aggressive climates, insulation faces intense sunlight, high ambient temperatures, and even sandstorms. UV exposure can degrade certain insulation jacketing materials (making them brittle or cracked), and wind-blown sand can erode or infiltrate insulation if not perfectly sealed. Traditional insulation systems with cladding have joints and seams that can fail over time , providing entry points for water or sand. The result is that conventional insulation often requires regular inspection and maintenance to ensure it’s still effective.

Bulky and Installation Challenges: Materials like mineral wool or foam glass need substantial thickness to handle very high temperatures. This bulk is problematic when space is tight or on complex shapes like valve assemblies and elbows. Thick insulation can also be heavy, requiring strong support and adding weight to pipelines. Installation is typically labor-intensive as well – cutting and fitting batts, securing them with wire or bands, sealing with cladding – often requiring skilled insulators. And for high-temperature systems, traditionally one might need to shut down equipment to install or repair insulation safely, which leads to downtime.

Performance Limits: Each traditional material has an upper temperature limit and other drawbacks. Fiberglass, for instance, can compress and lose effectiveness at very high temperatures. Calcium silicate is excellent up to ~650°C but is rigid and can crack under vibration or thermal cycling. There’s also the phenomenon of the “critical insulation thickness” on small diameter pipes – if insulation is too thin on a small pipe, it can actually increase convective losses by raising the surface area; one must choose an appropriate thickness to truly reduce net heat loss. These nuances mean traditional insulation must be carefully engineered for each situation, and even then, some heat loss remains.

The bottom line is that while conventional insulations do help, they come with maintenance burdens and may not always perform optimally in severe conditions. A need emerged for better insulation technology that can overcome these challenges – offering high performance, moisture resistance, and easier application. This need has led to advanced insulation solutions being adopted in the oil and gas sector.

Advanced Insulation Technologies: Nano-Ceramic Coatings and More

Recent years have seen the rise of innovative insulation technologies designed to address the shortcomings of older materials. Among the most promising for industrial use are nano-ceramic thermal insulation coatings. Products like ISOLLAT – a liquid-applied nano-ceramic insulation – are game-changers for insulating equipment in oil & gas and other industries. Instead of wrapping bulky mats or foam, these solutions are applied like a paint or coating, curing into a thin layer that provides powerful thermal resistance.

What is nano-ceramic insulation? In the case of ISOLLAT, it is an advanced formulation containing microscopic ceramic particles (nanoparticles) suspended in a liquid medium. When applied to a surface (by spray or brush), it dries into a seamless insulating barrier. The nano-ceramic particles have extremely low thermal conductivity and also reflect heat radiation, effectively blocking heat transfer in all forms. According to the manufacturer, ISOLLAT is engineered to combat heat transfer, reduce energy consumption, and protect critical infrastructure . Unlike conventional blankets, a ceramic coating creates a tight bond to the surface with no gaps or joints, which means no places for moisture to ingress or heat to “sneak” through uninsulated spots. The end result is a high-performance insulation layer only a couple millimeters thick.

Some key advantages of nano-ceramic insulation coatings like ISOLLAT include:

Significant Energy Savings: Despite its thin profile, this insulation is highly effective. Facilities using nano-ceramic coatings report up to 40% energy savings on insulated equipment . By drastically cutting heat loss (or heat gain, in the case of chilled systems), the coating brings immediate reductions in fuel or power use to maintain temperatures.

Reduced Heat Loss and Heat Gain: In hot processes, the coating minimizes heat escaping. Conversely, if applied to cold lines or LNG tanks, it minimizes heat coming in. This bidirectional thermal protection helps keep processes at their setpoint. Field data shows a significant reduction in heat loss or heat gain after applying the coating

Ultra-Thin, Space-Saving Application: Because it can do the job in a layer often just 2–3 mm thick, nano-ceramic insulation frees up space. It’s ideal for confined or hard-to-reach areas where wrapping 50 mm of mineral wool would be impractical. The minimal space requirement is a big advantage on densely packed skids or around complex geometries like valve clusters . It adds negligible weight and doesn’t require large clearance around pipes.

Corrosion Prevention (No CUI Risk): ISOLLAT’s nano-ceramic thermal insulation technology helps eliminate corrosion under insulation (CUI) by design. Unlike traditional systems like Rockwool, which require external cladding and can trap moisture, ISOLLAT is a cladding-free solution that is water-resistant and water-vapor permeable. This allows any trapped moisture or vapor to escape rather than accumulate. Its application prevents moisture from remaining within the insulation layer, removing the key conditions that lead to CUI. By eliminating trapped condensation and external water ingress, ISOLLAT ensures longer asset life and reduced maintenance needs.

Easy Application with Minimal Downtime: Applying a nano-ceramic insulation is straightforward – it can be sprayed on or brush-painted, even onto hot surfaces if necessary. There is no need for custom cutting or fitting. In many cases, insulation can be applied without shutting down equipment, as the coating can cure quickly and safely at operating temperatures . This is a stark contrast to traditional insulation work that might require a maintenance shutdown. The installation labor is simpler (similar to painting) and does not require highly skilled insulators, which can reduce labor costs as well

High Thermal Reflectivity: The ceramic particles reflect radiant heat effectively. Tests show these coatings can reflect up to 95% of infrared and ultraviolet rays . This means that on a sunexposed pipe or tank (common in Middle Eastern oilfields), the insulation reflects away the sun’s heat during the day, keeping the contents cool, and at night it keeps the process heat from radiating out. Traditional insulation cannot offer this radiation reflection to that degree. High reflectivity is especially useful for insulating against solar heat gain on storage tanks or pipelines running above ground.

Wide Operating Temperature Range:

ISOLLAT’s advanced nano-ceramic insulation is engineered to withstand extreme thermal conditions—from -60°C up to +700°C. This broad range makes it suitable for both cryogenic pipelines and high-temperature steam lines, covering a wide spectrum of oil & gas and industrial applications with a single solution. The material also resists thermal shock and repeated temperature cycling without cracking, maintaining consistent performance in demanding environments.

Longevity and Durability: Nano-ceramic coatings are designed to last for years. They are UVresistant, do not degrade quickly, and often come with long service life (10+ years) without performance loss . They also do not require an outer cladding for protection – once cured, the coating itself is typically weatherproof and can even be tinted (colored) for identification or aesthetic purposes. This eliminates the extra step of jacketing and the potential failure points that come with it.

All these benefits make nano-ceramic insulation a revolutionary solution for the oil & gas sector. It essentially tackles the weaknesses of conventional insulation: it’s thin instead of bulky, moisture-sealed instead of moisture-vulnerable, and easy to apply instead of labor-intensive. The result is greater heat retention with fewer headaches.

One real-world example of its effectiveness: Saudi Aramco, the world’s largest oil company, tested the nanoceramic coating for extreme high-temperature insulation. In one project, they were able to reduce a surface’s temperature from 500 °C down to just 60 °C using a non-metallic nano-ceramic insulation system . This astonishing drop illustrates how powerful the technology can be, even on blisteringly hot equipment. And it was achieved with a fraction of the thickness that traditional insulation would require.

The Middle East Focus: Insulation in KSA, UAE, and the GCC

The Gulf Cooperation Council (GCC) countries – notably Saudi Arabia and the United Arab Emirates – present some of the harshest operational conditions and unique motivations for thermal insulation. The climate is characterized by extreme heat, intense sun, and dry conditions. Paradoxically, while these nations are leading oil & gas producers, they also have strong incentives to use energy more efficiently domestically.

In Saudi Arabia (KSA), for example, massive initiatives are underway to improve energy efficiency across all sectors. Saudi Vision 2030 has set strict energy efficiency targets and guidelines, even mandating thermal insulation in new buildings to curb electricity use for air conditioning . In industry, the Saudi Energy Efficiency Center (SEEC) has worked on programs to optimize energy use in petrochemicals, refining, and other heavy industries. Reducing waste heat losses in these industries is a low-cost way to meet such targets. Every BTU saved through insulation is a BTU of oil or gas that can either be exported for revenue or used in value-added processes, rather than burned needlessly. It’s no surprise that Saudi Aramco and other regional operators have been actively upgrading insulation as part of energy management and emissions reduction plans.

The UAE likewise has sustainability strategies (like the UAE Energy Strategy 2050 and Dubai’s Clean Energy Strategy) that emphasize energy efficiency in industry. With temperatures soaring above 50 °C in summer, any heat loss from a process not only wastes energy but also adds to the burden on cooling systems and the overall heat load in facilities. UAE refineries and LNG terminals are starting to adopt advanced insulations to keep processes efficient against the challenging ambient conditions.

One major challenge in the region is the high ambient temperature itself. Traditional insulation is usually designed to keep heat in, but in the Gulf, when ambient air is 45 °C, insulation might also be needed to keep heat out of chilled or cryogenic systems, or to protect sensitive equipment from the searing sun. Advanced materials like nano-ceramic coatings excel here because of their reflective properties (as mentioned, reflecting UV and IR). They can shield equipment from the desert sun effectively, acting as a thermal barrier in both directions (keeping heat in during winter nights and out during summer days).

Another factor is the aggressive environment: UV exposure and occasional sandstorms. Coatings like ISOLLAT have an advantage in being UV-stable and forming a continuous skin that sand and dust can’t easily penetrate. They adhere well to surfaces even in fluctuating temperatures. By contrast, if a section of metal cladding on traditional insulation gets blown off or sand-abrasion creates a gap, the insulation underneath can get compromised. The robustness of advanced coatings offers peace of mind in such conditions.

Economically, both KSA and UAE are looking to get more value from their energy. Wasting less heat means burning less fuel for the same output – directly aligning with goals to reduce per-unit energy consumption. Indeed, many GCC industries now recognize that thermal insulation is not just an afterthought, but a strategic investment. As one Gulf-based expert put it, industries in this region require insulation solutions that go beyond outdated bulky materials to meet modern efficiency demands . This has opened the door to products like ISOLLAT across oil & gas facilities, petrochemical plants, power generation units, desalination plants, and more

Adopting cutting-edge insulation also helps GCC companies meet international standards and environmental regulations. For instance, by improving insulation, a plant can reduce its greenhouse gas emissions (by burning less fuel), aiding compliance with any future carbon-credit or carbon-tax frameworks . It also contributes to corporate sustainability pledges, which many national oil companies and industrial giants in the Middle East have begun to make as part of global climate initiatives.

Finally, there is a safety and work environment aspect. In Saudi Arabia and UAE’s hot climate, working around uninsulated equipment can be extremely uncomfortable if not dangerous for staff. Properly insulated equipment not only conserves energy but also keeps the facility safer and cooler for personnel. This improves working conditions, which is an important consideration in regions where protecting workers from heat stress is a constant challenge. Advanced insulations that ensure safer surface temperatures and prevent random hot spots thus support occupational safety goals in these countries

Conclusion: Insulation as a Strategic Priority

Heat transfer losses in the oil and gas sector might not always grab headlines, but they are a silent thief of energy, efficiency, and profits. In an era where margins can be thin and sustainability is paramount, it’s clear that insulation is your first line of defense to combat these losses. By installing effective thermal insulation on pipes, tanks, and equipment, companies can immediately plug energy leaks and reap multiple benefits – from lower fuel bills and improved process stability to enhanced safety and longer equipment life.

Traditional insulation materials have served industry for decades, but their drawbacks (moisture issues, bulk, maintenance needs) leave room for improvement. Fortunately, modern solutions like nano-ceramic insulation coatings are rising to the challenge. They offer high-performance thermal protection without the downsides of old materials. As demonstrated with technologies like ISOLLAT, a thin layer of advanced insulation can outperform inches of conventional insulation, saving up to 40% of energy on insulated equipment in real-world cases . These coatings also address critical issues like CUI and installation downtime, making them especially suited for upgrading aging facilities.

For companies operating in the Middle East (Saudi Arabia, UAE, and beyond) – where both the climate and national efficiency agendas demand top-tier performance – embracing advanced insulation is a smart move. It aligns with the region’s vision for energy efficiency (such as Saudi Vision 2030) and helps industrial players stay competitive and compliant in a global market that increasingly values sustainability. Insulation might not be as glamorous as a new reactor or drilling technology, but its impact on the bottom line and the environment is profound. As one industry blog aptly noted, overlooking insulation means overlooking one of the highest-impact efficiency measures available

In conclusion, investing in quality insulation – especially leveraging cutting-edge nano-ceramic technology – should be a priority for any oil & gas operation aiming to reduce heat transfer losses. It is a cost-effective step that offers immediate returns and long-term gains. By treating insulation as the first line of defense, companies can ensure that heat stays where it belongs: working for the process, not escaping into the air. The result is energy saved, costs saved, and a safer, greener, more efficient industry. In the challenging environments and competitive markets of today’s oil and gas sector, that is a formula for success.

Comments