Minimising Steam Line and Tank Heat Loss in Middle East: Cladding Free Thermal Insulation System ISOLLAT’s Energy Efficiency Solution

- Omar Obaid

- Jul 30, 2025

- 8 min read

Introduction

Energy efficiency is a top priority for industrial facilities, especially in the Gulf region where extreme temperatures and massive oil & gas operations demand effective thermal management. One often overlooked opportunity for savings is in insulating equipment like steam lines and storage tanks, which can otherwise lose or gain heat rapidly in harsh climates. Traditional insulation (like mineral wool or foam) comes with drawbacks – it’s bulky, prone to moisture damage, and struggles to protect complex shapes or outdoor tanks in the desert environment . Enter ISOLLAT, a nano-ceramic liquid thermal insulation coating that is redefining how industries conserve energy. This advanced coating can be applied as a thin layer on surfaces to dramatically reduce heat transfer, thereby cutting energy losses and improving safety without the usual maintenance headaches of conventional insulation

The Gulf’s Industrial Insulation Challenge

In Gulf countries, industries face unique insulation challenges. Scorching daytime heat followed by cooler nights means equipment experiences constant thermal cycling. For steam pipelines, any heat loss forces boilers to work overtime to keep steam hot, wasting fuel. Likewise, storage tanks holding hot products (or even chilled fluids) can suffer huge temperature swings due to intense sun exposure and high ambient temperatures. Conventional insulation materials require thick layers and metal cladding to perform in these conditions – and even then, they risk corrosion under insulation (CUI) when desert sandstorms or coastal humidity drive moisture into the insulation . Maintaining these bulky insulations is costly and often requires downtime. Clearly, Gulf industries have been eager for a better solution that keeps heat in (or out) efficiently, resists weather and corrosion, and is easier to apply on everything from long pipeline networks to massive tank farms.

ISOLLAT: A Nano-Ceramic Insulation Solution

ISOLLAT is a liquid-applied nano-ceramic thermal insulation coating engineered to meet these tough requirements. Developed with a matrix of hollow ceramic microspheres and high-performance acrylic binders, ISOLLAT creates a seamless insulating layer only a few millimeters thick . Despite its minimal profile, this coating packs powerful thermal performance – with an extremely low thermal conductivity (as low as 0.002–0.007 W/m·K) that rivals or outperforms traditional insulation . Once sprayed or painted on, ISOLLAT bonds directly to the surface (metal, concrete, etc.) and dries to form a durable, white reflective film. The bright ceramic-filled coating reflects and re-emits up to 99% of incident radiant energy, meaning solar heat or thermal radiation is mostly bounced away rather than absorbed . This high reflectivity is especially valuable for tank exteriors under the Arabian sun, and it complements the coating’s inherent conduction insulation properties to keep asset temperatures stable.

How does ISOLLAT differ from conventional insulation? For one, it does more than just insulate. ISOLLAT also contains corrosion-inhibiting components and is waterproof once cured, effectively sealing the surface against moisture and rust . By adhering directly to pipes or tank walls, it leaves no gaps for moisture ingress and eliminates the need for metal cladding or jacketing . The coating is non-flammable and UV-stable, so it won’t degrade under desert sun or pose a fire hazard . Additionally, ISOLLAT remains elastic up to 200% elongation allowing it to expand and contract with the substrate during temperature changes without cracking . This flexibility and strong adhesion mean it can coat complex shapes – from valves and flanges to curved tank roofs – which are often impossible to fully cover with traditional insulation wraps . The result is a continuous, monolithic insulation layer that requires little to no maintenance and can last 15–20+ years in service without performance loss

Energy Efficiency on Steam Lines

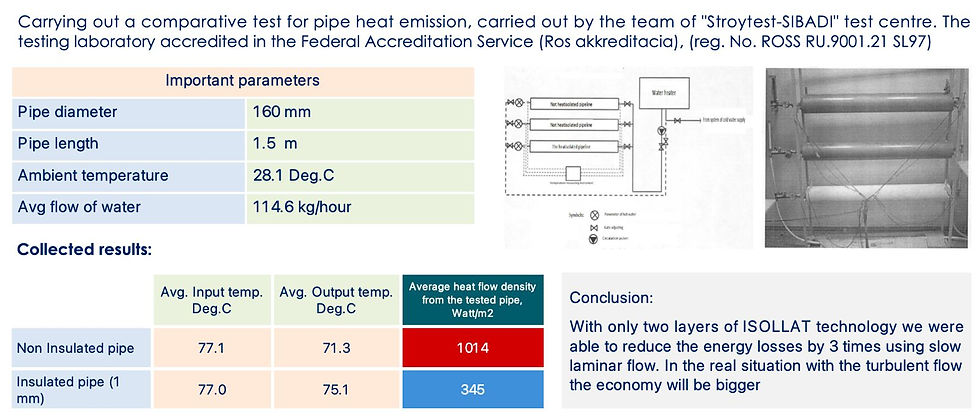

Steam lines are the arteries of refineries, power plants, and petrochemical facilities across the Middle East. These pipes carry high-temperature steam to where it’s needed, but without proper insulation they radiate heat and waste energy. ISOLLAT provides a game-changing way to insulate steam pipelines with minimal thickness. Applied as a coating (typically 1–2 mm thick), ISOLLAT dramatically cuts down heat loss along the pipe’s length. In one test, a bare steel pipe at ~77°C surface temperature was insulated with just 1 mm of ISOLLAT, resulting in a nearly threefold reduction in heat loss through the pipe wall . Another industrial trial showed an uninsulated pipe section losing ~1475 W/m² of heat, which dropped to only ~189 W/m² after ISOLLAT was applied – an 87% reduction in heat loss These results translate to significant fuel savings for boilers, as less energy is needed to maintain steam temperature. Over many kilometers of steam lines, the energy (and cost) savings accumulate quickly.

Beyond energy economics, using ISOLLAT on steam lines improves workplace safety and reliability. The coating brings exposed surface temperatures down to safe levels – for example, surfaces that were over 120°C can drop below 55°C, making them safe to touch and eliminating burn hazards for personnel . By preventing heat loss, the coating also helps maintain steam quality (avoiding condensation in the lines) which means less strain on traps and pumps. And since ISOLLAT is applied directly to the pipe, there’s no risk of fibers or cladding coming loose; the coating won’t absorb water or fall apart, even in humid or coastal Gulf environments. Maintenance teams appreciate that inspections or repairs are easier – there’s no need to strip off insulation for non-destructive testing (NDT) or leak checks, as ISOLLAT’s thin layer can stay in place and even visually show any issue (e.g. a rust spot or leak will be visible, not hidden under cladding) . All of this keeps steam systems running more efficiently with less downtime

Energy Efficiency in Storage Tanks

Large storage tanks – whether holding hot fuel oil, chemicals, water, or other liquids – are another area where ISOLLAT shines. Tanks have vast surface areas that exchange heat with the environment. Traditionally, insulating a field of tanks involves wrapping them in thick mineral wool and metal cladding, which is labor-intensive and eventually prone to weather damage or CUI. In contrast, ISOLLAT can be spray applied directly to a tank’s exterior (or interior for certain applications) to form a continuous thermal barrier. The coating’s dual action of thermal insulation and solar reflectance is particularly beneficial here. By insulating, it keeps stored liquids at their intended temperature longer – reducing the need for reheating heated tanks or preventing chilled tanks from warming up. By reflecting sunlight (thanks to a >90% solar reflectance if white), it also prevents extra heat gain during the day . This means, for example, a tank of heated fuel oil used as backup fuel will stay hot with far less input energy when coated with ISOLLAT, even under direct sun in a Gulf summer. In fact, using ISOLLAT on heated fuel tanks has been shown to significantly cut the boil-off or heat loss rate, allowing long-term hot storage with minimal energy input. Similarly, a water tank treated with ISOLLAT will be protected from solar heating, keeping the water cooler and reducing cooling costs or water degradation

Another key advantage for tanks is condensation control. In humid coastal areas or cool nights, uninsulated tanks can develop condensation on their surfaces, leading to water pooling and corrosion. ISOLLAT’s insulating and moisture-resistant nature keeps the surface temperature above the dew point, eliminating condensation formation on the tank surface . This protects both the tank’s paint/coating and the stored product quality. And because ISOLLAT is vapor-permeable but liquid-tight, it lets the tank “breathe” without trapping moisture against the metal . The outcome is greatly reduced corrosion risk – a crucial factor for the longevity of expensive storage assets. Plant operators in the Middle East also value the fact that ISOLLAT doesn’t add significant weight or wind load to tank roofs and walls, unlike heavy conventional insulation. A 2 mm coating is almost weightless in comparison and won’t catch the wind or sand. Plus, with no external cladding needed, there’s nothing for the strong desert winds to strip off or for salt air to seep under – the protective layer stays intact for decades

Key Benefits of ISOLLAT for Industrial Energy Efficiency

Substantial Energy Savings: By minimizing heat transfer, ISOLLAT reduces energy losses in pipes and tanks. Facilities have reported up to 40% energy savings after switching from traditional insulation to ISOLLAT on hot systems 34 . This directly lowers fuel consumption and operating costs while also cutting carbon emissions as less fuel is burned.

All-Weather Durability: ISOLLAT is formulated to withstand harsh conditions – from -60°C cold to 700°C heat 35 36 37 . Its UV-resistant, waterproof coating shrugs off desert sun, sand, and salt air without cracking or degrading. Even in 100% humidity or high wind, the insulation performance remains stable . This reliability ensures energy efficiency benefits continue year-round in Gulf climates.

Corrosion and CUI Prevention: Unlike conventional insulation systems that can trap moisture and hide corrosion, ISOLLAT offers a breathable insulation layer. Its water vapor permeability prevents moisture accumulation, allowing the substrate to “breathe” and significantly reducing the risk of corrosion under insulation (CUI). Additionally, ISOLLAT is formulated with corrosion inhibitors that help delay and slow down the onset of corrosion, even under harsh environmental conditions. With no need for cladding and no risk of moisture entrapment, ISOLLAT contributes to longer asset life, better surface visibility, and reduced maintenance requirements — helping preserve asset integrity while minimizing heat loss.

Space & Weight Savings: The coating’s ultra-thin profile (0.5–3 mm) adds negligible thickness and weight to equipment 6 38 . This is a huge advantage for congested plants and tall tanks, where bulky insulation would be impractical. ISOLLAT provides the same (or better) thermal performance as insulation that is many centimeters thick, freeing up space and reducing structural load.

Easy Application & Maintenance: Applying ISOLLAT is straightforward – it can be sprayed on in-situ without shutting down equipment . Two workers can cover up to 1,500–2,000 m² in a day , much faster than installing traditional insulation. Once applied, it requires little maintenance (no jackets to repair, no material settling). If a section is ever damaged, you can simply recoat that spot no need to replace entire sections 40 39 . This ease of use translates to lower lifetime costs and minimal downtime, further enhancing overall energy efficiency.

Conclusion

From high-temperature steam lines crisscrossing refineries to sprawling storage tanks baking in the desert sun, ISOLLAT has proven its value as a next-generation insulation solution for the Gulf’s industrial sector. By combining advanced nano-ceramic technology with practical on-site applicability, ISOLLAT helps companies save energy, improve safety, and protect assets in ways traditional insulation cannot match. The coating’s ability to drastically cut heat losses while enduring harsh environmental conditions makes it especially suited for Middle East facilities aiming to boost efficiency and sustainability. In an era where every percentage of energy saved counts – both for the bottom line and for emissions goals – ISOLLAT’s role in energy efficiency is increasingly vital. Gulf industries of all kinds (oil & gas, petrochemicals, power generation, manufacturing, and more) are finding that whether it’s steam lines, storage tanks, or nearly any equipment in between, this innovative insulation coating delivers a durable, high-performance thermal barrier. ISOLLAT exemplifies how smart coating technology can tackle longstanding challenges, helping industrial operators in the region achieve new standards of efficiency and reliability

Comments